EXPLORATION

Laser Engraving PETG

Recently, we’ve been working more with PETG. Since there’s already plenty of content out there comparing the basic experiences of printing with PLA and printing with PETG, we’ll focus here on some of our observations that may be more unique to the intersection between 3D printing and laser marking.Recently, we’ve been working more with PETG. Since there’s already plenty of content out there comparing the basic experiences of printing with PLA and printing with PETG, we’ll focus here on some of our observations that may be more unique to the intersection between 3D printing and laser marking.

Reference files can be found in the Materials Reference accordion at the bottom of the page

PLA vs PETG

Same colors, different results

The first apparent difference was that many PLA colors that the IR laser had little effect on, actually produced some usable results when PETG in those colors was used.

The following is by no means a complete or exhaustive sample set, but hopefully it’s enough to draw some initial conclusions about a project you may have in mind.

Multiple colors tested

For this test we used the xTool F1’s 2W IR laser

White

The IR laser on the white PLA produced no detectable effect; while on the PETG, it produced a range of darker, slightly warm grey values.

Bambu PLA 1.75mm White

Overture PETG 1.75mm White

Light Grey

The IR laser on the light grey PLA produced white markings, while on the PETG, it produced a range between an off-white (at longer duration) to a warm, darker, brownish-grey (at shorter duration).

Polymaker Polylite PLA PRO 1.75mm Grey

Polymaker Polylite PETG 1.75mm Grey

Orange

The IR laser on the orange PLA produced no detectable effect, while on the PETG, it produced dark markings; that were slightly raised to the touch. Longer durations produced darker marks, higher surface reliefs (but also had a higher tendency to begin blistering).

eSun PLA+ 1.75mm Orange

SUNLU PETG 1.75mm Orange

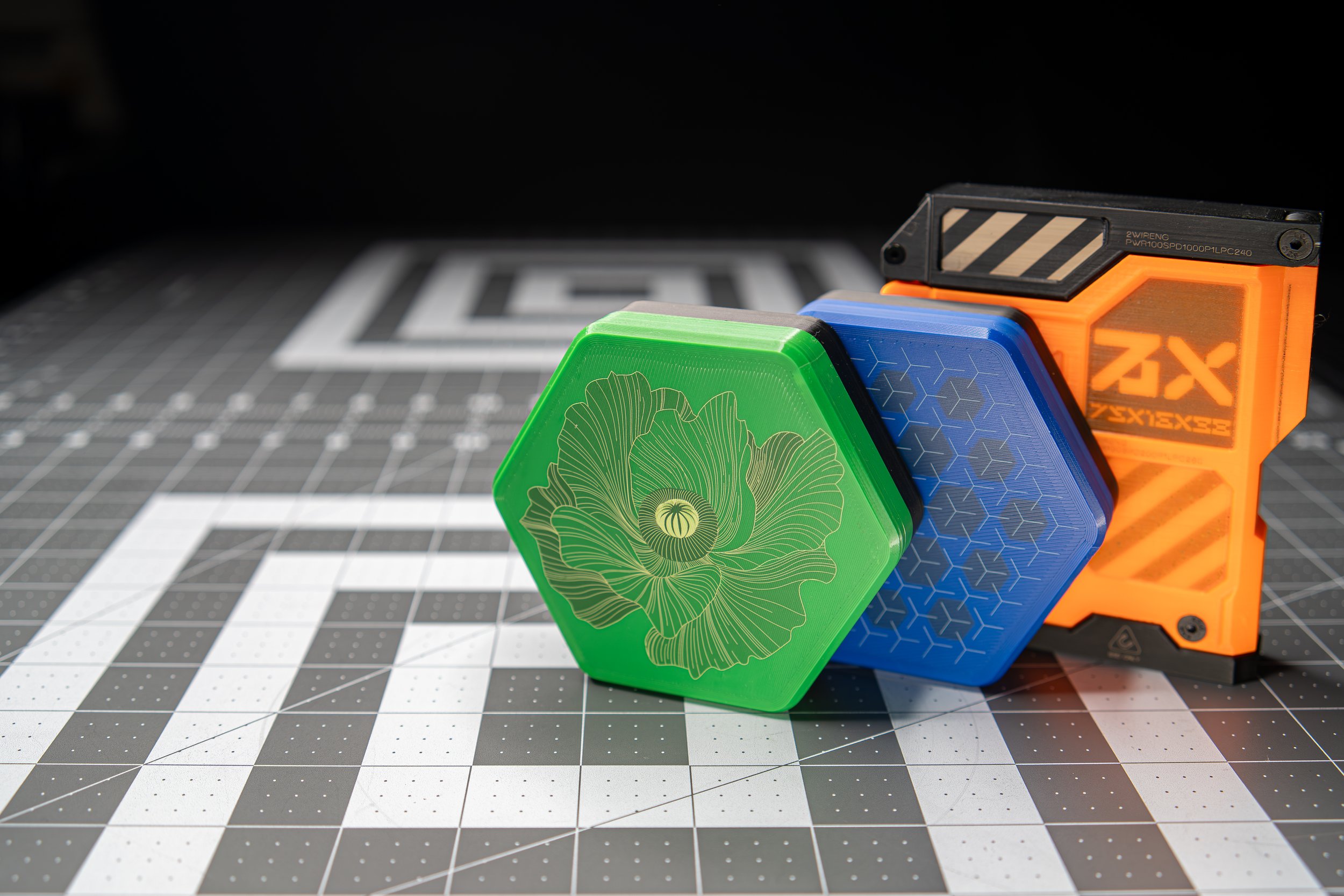

Green

The IR laser produced slightly darker, barely visible marks on the green PLA; while on the PETG the markings spanned from a lighter yellow (at longer durations/higher power) and darker grey-brown (at shorter durations/lower power).

CC3D PLA MAX 1.75mm Classic Green

Geeetech PETG 1.75mm Green

Blue

The IR laser on blue PLA yielded no detectable results; while on blue PETG, the effect ranged from a slightly warm white to warm dark grey, depending on settings. Interestingly, there seemed to be a duration ‘sweet-spot’ for getting even coverage of the off-white (about 300 mm/sec at 240 l/cm at full power; or 180 mm/sec at 180 l/cm at full power; or 200 mm/sec at 240 l/cm at 70% power). Beyond that, the material begins to melt.

Hatchbox PLA Pro+ 1.75mm Blue

Overture PETG 1.75mm Blue

Black

Black PLA and black PETG behaved very similarly when subjected to the IR laser. Even optimal settings seemed to be very similar, both favoring shorter durations for getting the lightest, highest-contrast marking.

Polymaker PLA Pro 1.75mm Black

Polymaker PETG 1.75mm Black

Using the 10W 455nm Blue Diode laser on Black PETG

SUNLU PETG 1.75mm Black

Here is a link to the xTool file we used for the tests:

Some Observations

As with PLA, darker colors in PETG yielded a more usable range. In fact, black PETG behaved very similarly to black PLA; with the setting range being similar enough to be usable for both materials; albeit the PETG having slightly darker marking throughout the range overall.

Another observation to note was that with PETG, darker marking was part of the effect range. This is unlike PLA which usually yields lighter marking as the plastic foams when the laser hits the surface.

With PETG, it seems while at some settings, the laser will also foam the plastic creating the lighter marks; but at other settings, it will evenly burn or scorch the material. Applied carefully, both of these effects can be used to add visual range to a design.

One last thing we discovered was a neat lenticular-like effect with the orange PETG. This particular filament was more translucent than the other colors of PETG we used for the test, so that may have been a factor.

-

If you are interested in what we used for this process, you can find our materials below.

Hardware:

Bambu X1 Carbon

WhamBam 258 x 258 Flexi Plate with Pre-Installed PEX Build Surface

xTool F1

Software:

Shapr3D Version 5.692.0 (7363)

Bambu Studio 1.9.3.50xTool Creative Space v2.0.117-beta

-

-

*Please remember that using lasers on synthetic materials always runs the risk of putting harmful chemicals into the air. So, before beginning, don't forget to ensure that you have proper ventilation and to use hoods and air filtration whenever possible.